Learn how Resilinc is using predictive AI and generative AI to innovate supply chain risk management.

In part one of our AI in supply chain blog series, “How is AI Revolutionizing Supply Chain Risk Management?”, we sat down with Resilinc’s Associate Vice President of Product Management, Shahzaib Khan, to learn about Resilinc’s ongoing investment in AI. In our Q&A, Shahzaib discussed predictive AI, which is used for supply chain disruption monitoring, hurricane simulators, commodity predictions, supplier screening, and predictive purchase orders. Shahzaib also touched on Generative AI, which is used in Resilinc’s supply chain disruption alert system, EventWatchAI.

In part two of our series, we will explore the key differences between predictive AI and generative AI and their unique applications for enhancing supply chain risk management. If you are considering incorporating AI into your SCRM program, this blog can give you a foundation of understanding which one will be most helpful.

As the name alludes, predictive AI helps make predictions. It answers the question, “What might happen in the future?” by analyzing past data. Data—particularly high-quality data and large amounts of data—is essential to predictive AI. The more high-quality data used to train the AI, the smarter and more accurate the predictions will be. Because of this, predictive AI is an excellent match for supply chain risk management since it can help businesses have visibility into potential trends, risks, and solutions. Predictive AI has been used in numerous unique applications outside the supply chain. For example it has been used to:

Predictive AI is great for providing visibility and quickly offering insights to solve problems and mitigate disruptions. It makes supply chain risk management more proactive and helps customers mature their SCRM programs. Before we dive into Resilinc’s AI-powered solutions, here’s a look at some of the broader ways Resilinc’s AI helps customers manage and predictive risks.

Predictive Insights: Predictive AI models forecast potential disruptions, bottlenecks, and adverse events in the supply chain. By analyzing historical data and considering factors such as market indicators and sub-tier relationships, graph neural networks (GNNs) provide valuable insights into future risks.

Real-Time Monitoring: GNNs continuously analyze evolving relationships within the supply chain, offering real-time insights and alerts regarding emerging risks. This real-time capability is crucial for proactive risk management.

Supplier Network Optimization: GNNs recommend alternative sub-tier suppliers in case of disruptions or risks associated with specific suppliers. This helps diversify the supply chain, reduce over-reliance on critical suppliers, and mitigate risks.

Supply Chain Resilience: Predictive AI models assist in developing contingency plans by simulating various risk scenarios. This enhances a supply chain’s ability to adapt to unforeseen events and ensure the continuity of operations.

Data-Driven Decision-Making: Predictive models AI provide data-driven insights that empower supply chain managers to make informed choices regarding risk mitigation, contingency planning, and overall supply chain strategy.

Because of the many benefits, Resilinc leverages predictive AI in several ways to enhance supply chain risk management, such as disruption monitoring, predicting delays in purchase orders (POs), predicting fluctuations in commodity prices and supply constraints, autonomous sub-tier mapping, risk scoring models, supplier screening, and scenario simulators.

In some cases, Predictive AI works together with other AI models, including classification models, clustering models, and recommendation models. These other models were trained on several data sets: historical data provided by customers and third-party data, as well as Resilinc’s 12+ year wealth of supply chain data.

Let’s take a closer look at our solutions powered by predictive AI and the specific models they use:

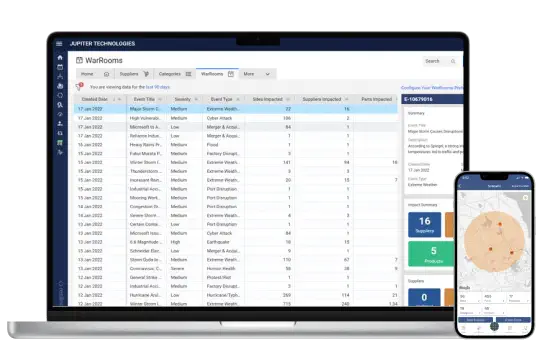

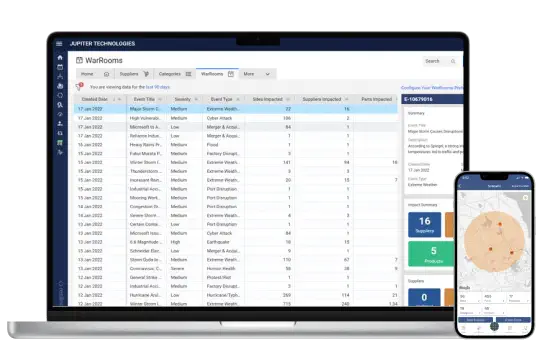

Monitors and alerts customers of 400 disruptive scenarios across 41 supply chain risks 24/7—and receives about 8 million rows of data daily. Without a proper, robust AI-based system, dealing with this vast amount of data would be impossible. EventWatchAI also uses Natural Language Processing (NLP) to identify disruptions in near-real time and create a virtual supply chain disruption WarRoom where customers can respond to disruptions. Learn how EventWatchAI helped companies take early action during the pandemic in this whitepaper: Early COVID-19 Timeline: The Value of Detection, Information, and Early Action.

This tool leverages AI to identify how a supplier will perform by analyzing past events and on-time delivery data. The AI that goes into Resilinc’s Specific PO delay prediction offering is a type of predictive model called a regression model, which predict continuous numerical values based on input features. The system handles more than 8 million data feeds every day. It can detect disruptions deep within multi-tiered supply chains and offer predictive insights into potential delays in purchase orders almost instantaneously. Customers utilize this capability to enhance their proactive approach to managing disruptions.

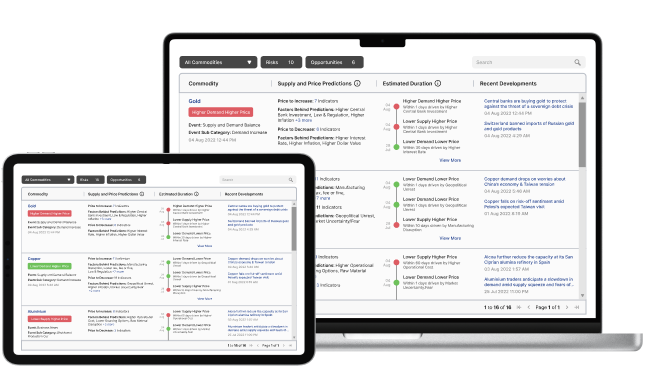

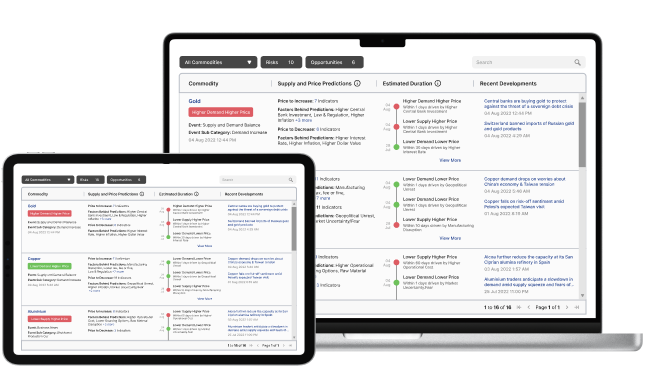

CommodityWatchAI is a predictive algorithm that predicts commodity price fluctuations and supply constraints more than three months out for materials such as copper, aluminum, and steel. It uses a predictive model of AI called “time series forecasting.” These models forecast future values within a time series data set. CommodityWatchAI uses a qualitative model that surfaces disruptions from global news and a quantitative model that receives a qualified data feed as input. These models work together to predict supply, demand, and prices for key raw materials. This patent pending model helps our customers’ teams and commodity managers make well-informed, data-driven decisions about the sourcing of key raw materials, empowering their negotiations.

Autonomous AI Mapping helps our customers uncover sub-tier relationships several tiers deep by looking at Residing’s 12+ years of supply chain data. For example, it can help find the location of warehouses, alternative suppliers, and more. Our Autonomous AI Mapping does this by heavily relying on Graph Neural Networks (GNNs), which are tailored to making knowledge graphs. These knowledge graphs help find connections between data from multiple sources. This risk data gets overlayed to make mapping more risk-oriented, which allows customers to solve more use cases like nearshoring.

Our risk-scoring models play a significant role in supplier profiling, relying on a range of clustering methodologies to segment suppliers based on various risk factors. Historic disruption data is used to quantify suppliers using a “supplier disruption vulnerability index.” This index provides the likelihood that a supplier will be affected by a disruption again in the future. It helps our customers identify suppliers that are vulnerable and initiate proactive risk mitigation measures for those suppliers.

For simulating real-world scenarios such as extreme weather like hurricanes and other disruptive events, we use Simulation Models. These models are used by customers every hurricane season to help predict the impacts of hurricanes and plan mitigation strategies in advance. Using simulation models provides actionable insights based on historic trends and predicts vulnerabilities across the supply chain for the future. Learn more in our webinar: Using AI for Hurricane Preparedness.

Generative AI has garnered a lot of attention lately with the advent of tools like ChatGPT (used to generate text) and Dall-E (used to create images). As the name implies, Generative AI can be used to generate text, images, videos, or other content depending on what data the models were trained on. Thanks to the broad nature of Generative AI, there are numerous applications, including:

Improving Customer Service: Generative AI can power chatbots that improve customer service and website experiences by helping customers in real-time. According to a recent poll from Gartner, 38% of executives said customer experience and retention were the primary reasons they invested in generative AI.

Creating Content: Natural language processing (NLP) tools like ChatGPT can be used in marketing to create copy, social posts, product descriptions, content outlines, and more.

Dealing with Large Data Sets: Data sets are growing larger and larger. Generative AI can help companies make large data sets more valuable by helping derive insights from a vast pool of information.

Today, after Predictive AI and NLP based models identify a supply chain disruption from an ocean of unstructured data, Generative AI helps EventWatchAI summarize and contextualize the event research in a timely fashion. Beyond EventWatchAI, Resilinc is starting to integrate cutting-edge AI models—such as Generative AI and Reinforcement Learning—across multiple facets of operations. This includes developing new risk models, code development, and enhancing internal data efficiency operations.

We are also working on solutions where Generative AI models produce prescriptive insights and dynamic playbooks based on historic supply chain disruption mitigation data. From there, the AI will learn how similar disruptive scenarios were handled in the past and generate actionable insights for the future. Finally, we are also looking at introducing a Generative AI chatbot that is linked to Resilinc’s database. For example, a customer could ask the model, “Can you give me all the locations that I have in Taiwan that are not in plastics?” Then, the chatbot will quickly analyze and respond with the correct data.

Artificial Intelligence is undeniably linked with the future of supply chain risk management. The nature of managing supply chains relies on real-time insights and accurate predictions—which are increasingly powered by AI. At Resilinc, we’ve embraced AI as a cornerstone of our products, providing enhanced visibility for our clients across every industry. As new technology emerges, we’re committed to continued innovation, leveraging AI to tackle our customers’ supply chain challenges with agility and precision.

Resilinc’s mission, since 2010, has been to build resilient, sustainable, and secure supply chains. Our dedication to supply chain resilience drives us to empower organizations with AI and data-backed solutions. Ready to experience the power of Resilinc’s AI technology combined with our expert team? Request a demo today to experience how Resilinc can help you respond to disruptions, mitigate risks, and transform challenges into opportunities.

The post Predictive AI vs. Generative AI in Supply Chain Management appeared first on Resilinc.

In part one of our AI in supply chain blog series, “How is AI Revolutionizing Supply Chain Risk Management?”, we sat down with Resilinc’s Associate Vice President of Product Management, Shahzaib Khan, to learn about Resilinc’s ongoing investment in AI. In our Q&A, Shahzaib discussed predictive AI, which is used for supply chain disruption monitoring, hurricane simulators, commodity predictions, supplier screening, and predictive purchase orders. Shahzaib also touched on Generative AI, which is used in Resilinc’s supply chain disruption alert system, EventWatchAI.

In part two of our series, we will explore the key differences between predictive AI and generative AI and their unique applications for enhancing supply chain risk management. If you are considering incorporating AI into your SCRM program, this blog can give you a foundation of understanding which one will be most helpful.

What is Predictive AI?

As the name alludes, predictive AI helps make predictions. It answers the question, “What might happen in the future?” by analyzing past data. Data—particularly high-quality data and large amounts of data—is essential to predictive AI. The more high-quality data used to train the AI, the smarter and more accurate the predictions will be. Because of this, predictive AI is an excellent match for supply chain risk management since it can help businesses have visibility into potential trends, risks, and solutions. Predictive AI has been used in numerous unique applications outside the supply chain. For example it has been used to:

- Diagnose breast cancer with the same accuracy as radiologists when given mammograms that show signs of cancer.

- Help understand the language of whales by analyzing vocalizations.

- Predict when bees swarm by measuring the sound of buzzing inside hives.

How Does Resilinc Use Predictive AI?

Predictive AI is great for providing visibility and quickly offering insights to solve problems and mitigate disruptions. It makes supply chain risk management more proactive and helps customers mature their SCRM programs. Before we dive into Resilinc’s AI-powered solutions, here’s a look at some of the broader ways Resilinc’s AI helps customers manage and predictive risks.

Benefits of Resilinc’s Predictive AI in SCRM

Predictive Insights: Predictive AI models forecast potential disruptions, bottlenecks, and adverse events in the supply chain. By analyzing historical data and considering factors such as market indicators and sub-tier relationships, graph neural networks (GNNs) provide valuable insights into future risks.

Real-Time Monitoring: GNNs continuously analyze evolving relationships within the supply chain, offering real-time insights and alerts regarding emerging risks. This real-time capability is crucial for proactive risk management.

Supplier Network Optimization: GNNs recommend alternative sub-tier suppliers in case of disruptions or risks associated with specific suppliers. This helps diversify the supply chain, reduce over-reliance on critical suppliers, and mitigate risks.

Supply Chain Resilience: Predictive AI models assist in developing contingency plans by simulating various risk scenarios. This enhances a supply chain’s ability to adapt to unforeseen events and ensure the continuity of operations.

Data-Driven Decision-Making: Predictive models AI provide data-driven insights that empower supply chain managers to make informed choices regarding risk mitigation, contingency planning, and overall supply chain strategy.

Resilinc Solutions: How Customers are Using Predictive AI

Because of the many benefits, Resilinc leverages predictive AI in several ways to enhance supply chain risk management, such as disruption monitoring, predicting delays in purchase orders (POs), predicting fluctuations in commodity prices and supply constraints, autonomous sub-tier mapping, risk scoring models, supplier screening, and scenario simulators.

In some cases, Predictive AI works together with other AI models, including classification models, clustering models, and recommendation models. These other models were trained on several data sets: historical data provided by customers and third-party data, as well as Resilinc’s 12+ year wealth of supply chain data.

Let’s take a closer look at our solutions powered by predictive AI and the specific models they use:

#1 EventWatchAI

Monitors and alerts customers of 400 disruptive scenarios across 41 supply chain risks 24/7—and receives about 8 million rows of data daily. Without a proper, robust AI-based system, dealing with this vast amount of data would be impossible. EventWatchAI also uses Natural Language Processing (NLP) to identify disruptions in near-real time and create a virtual supply chain disruption WarRoom where customers can respond to disruptions. Learn how EventWatchAI helped companies take early action during the pandemic in this whitepaper: Early COVID-19 Timeline: The Value of Detection, Information, and Early Action.

#2 Specific PO delay prediction

This tool leverages AI to identify how a supplier will perform by analyzing past events and on-time delivery data. The AI that goes into Resilinc’s Specific PO delay prediction offering is a type of predictive model called a regression model, which predict continuous numerical values based on input features. The system handles more than 8 million data feeds every day. It can detect disruptions deep within multi-tiered supply chains and offer predictive insights into potential delays in purchase orders almost instantaneously. Customers utilize this capability to enhance their proactive approach to managing disruptions.

#3 CommodityWatchAI

CommodityWatchAI is a predictive algorithm that predicts commodity price fluctuations and supply constraints more than three months out for materials such as copper, aluminum, and steel. It uses a predictive model of AI called “time series forecasting.” These models forecast future values within a time series data set. CommodityWatchAI uses a qualitative model that surfaces disruptions from global news and a quantitative model that receives a qualified data feed as input. These models work together to predict supply, demand, and prices for key raw materials. This patent pending model helps our customers’ teams and commodity managers make well-informed, data-driven decisions about the sourcing of key raw materials, empowering their negotiations.

#4 Autonomous AI Mapping

Autonomous AI Mapping helps our customers uncover sub-tier relationships several tiers deep by looking at Residing’s 12+ years of supply chain data. For example, it can help find the location of warehouses, alternative suppliers, and more. Our Autonomous AI Mapping does this by heavily relying on Graph Neural Networks (GNNs), which are tailored to making knowledge graphs. These knowledge graphs help find connections between data from multiple sources. This risk data gets overlayed to make mapping more risk-oriented, which allows customers to solve more use cases like nearshoring.

#5 Risk-Scoring Models

Our risk-scoring models play a significant role in supplier profiling, relying on a range of clustering methodologies to segment suppliers based on various risk factors. Historic disruption data is used to quantify suppliers using a “supplier disruption vulnerability index.” This index provides the likelihood that a supplier will be affected by a disruption again in the future. It helps our customers identify suppliers that are vulnerable and initiate proactive risk mitigation measures for those suppliers.

#6 Simulations

For simulating real-world scenarios such as extreme weather like hurricanes and other disruptive events, we use Simulation Models. These models are used by customers every hurricane season to help predict the impacts of hurricanes and plan mitigation strategies in advance. Using simulation models provides actionable insights based on historic trends and predicts vulnerabilities across the supply chain for the future. Learn more in our webinar: Using AI for Hurricane Preparedness.

What is Generative AI?

Generative AI has garnered a lot of attention lately with the advent of tools like ChatGPT (used to generate text) and Dall-E (used to create images). As the name implies, Generative AI can be used to generate text, images, videos, or other content depending on what data the models were trained on. Thanks to the broad nature of Generative AI, there are numerous applications, including:

Improving Customer Service: Generative AI can power chatbots that improve customer service and website experiences by helping customers in real-time. According to a recent poll from Gartner, 38% of executives said customer experience and retention were the primary reasons they invested in generative AI.

Creating Content: Natural language processing (NLP) tools like ChatGPT can be used in marketing to create copy, social posts, product descriptions, content outlines, and more.

Dealing with Large Data Sets: Data sets are growing larger and larger. Generative AI can help companies make large data sets more valuable by helping derive insights from a vast pool of information.

How Does Resilinc Use Generative AI in Supply Chain Risk Management

Today, after Predictive AI and NLP based models identify a supply chain disruption from an ocean of unstructured data, Generative AI helps EventWatchAI summarize and contextualize the event research in a timely fashion. Beyond EventWatchAI, Resilinc is starting to integrate cutting-edge AI models—such as Generative AI and Reinforcement Learning—across multiple facets of operations. This includes developing new risk models, code development, and enhancing internal data efficiency operations.

We are also working on solutions where Generative AI models produce prescriptive insights and dynamic playbooks based on historic supply chain disruption mitigation data. From there, the AI will learn how similar disruptive scenarios were handled in the past and generate actionable insights for the future. Finally, we are also looking at introducing a Generative AI chatbot that is linked to Resilinc’s database. For example, a customer could ask the model, “Can you give me all the locations that I have in Taiwan that are not in plastics?” Then, the chatbot will quickly analyze and respond with the correct data.

The Future of AI in Supply Chain Risk Management

Artificial Intelligence is undeniably linked with the future of supply chain risk management. The nature of managing supply chains relies on real-time insights and accurate predictions—which are increasingly powered by AI. At Resilinc, we’ve embraced AI as a cornerstone of our products, providing enhanced visibility for our clients across every industry. As new technology emerges, we’re committed to continued innovation, leveraging AI to tackle our customers’ supply chain challenges with agility and precision.

Resilinc’s mission, since 2010, has been to build resilient, sustainable, and secure supply chains. Our dedication to supply chain resilience drives us to empower organizations with AI and data-backed solutions. Ready to experience the power of Resilinc’s AI technology combined with our expert team? Request a demo today to experience how Resilinc can help you respond to disruptions, mitigate risks, and transform challenges into opportunities.

The post Predictive AI vs. Generative AI in Supply Chain Management appeared first on Resilinc.